3D printing was urban back in the early 80s, but it has seen much increase in the past ten years. At the moment, it has become one of the top growth areas in the tech industry and is revolutionizing industrialization, covering every business possible. The 3D printing company is, at the moment, a multi-billion dollar business and is likely to persist growing at an exponential speed. 3d printing powder manufacturers is moderately a simple development conceptually. The printers work by issue the chosen textile in layers on each other’s summit, with each layer situation before the next leave behind the printer.

Some critical point regarding printer

3D printers have been worn to print all types of materials, from offensive and standard materials to things we could anticipate to read in a sci-fi manuscript.

Plastics have entirely been used as the materials are despicable to acquire for the customer market. Still, more prominently, the technology obligatory to print synthetic is relatively uncomplicated and low cost.

Low-cost 3D printers using artificial tend to utilize Fused filament production (FFF). This is essentially a development where a twine of plastic is heated up to develop into pliable then supply through the machine layering the artificial. The devices usually use one of the following plastics.

Polylactic Acid: PLA is almost certainly the most comfortable textile to work with when we first start 3D make. It is an environmentally friendly cloth that is very protected to use. It is an environmental thermoplastic that has been derivative from renewable possessions such as corn starch and sugar canes. It is a comparable plastic that has been used in compostable luggage, which safely biodegrades evaluate to more conventional plastics used in Poly Bags.

Acrylonitrile butadiene styrene: ABS is the second most comfortable material to employment with when we start 3D printing. It is very safe and muscular and widely used for car bumpers and Lego the kid’s plaything.

Polyvinyl Alcohol Plastic: PVA plastic, which is moderately different from PVA stick. Please don’t endeavor to put PVA attach into our 3D Printer; it, without a doubt, won’t work. The accepted MakerBot Replicator 2 printers use PVA synthetic.

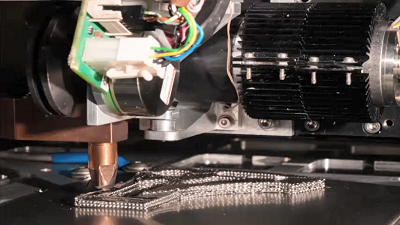

Plastics are used lengthily on all levels, from shopper to businesses prototyping new harvest. However, in the business marketplace, there is an enormous demand for metal 3D printing. Some printers should use crushed material that is then impassioned to produce a solid. This method is classically Direct Metal Laser Sintering (DMLS), and this scrupulous system is why we do not see customer metal 3D printing. DMLS necessitates an enormous amount of heat and giant posh printers to sinter the textile together. While 3D printing a metal object might be expensive than mass production, it is incredibly cost competent for composite and costly projects. A good instance of DMLS support 3D printing is GE Aviation using it for manufacturing 35,000 fuel injectors for its LEAP jet locomotive.

It is using tedious materials such as metal is roughly archaic in the world of 3D printing at this time; some companies at this time do 3D bioprinting, which is the development of creating cell model in a cramped space using 3D printing technologies, where cell job and viability has conserved within the printed make. These 3D bioprinters can print skin hankie, heart tissue, and blood vessels, among other fundamental tissues that would be suitable for surgical therapy and some transplantation.